Houston, Texas 77019-3908 USA

Phone: +1-832-654-4003

www.marineenergycorp.com

www.offshoreislandslimited.com

Open Ocean Current Catchers©

Marine Energy

Super Watt Wave Catcher Barges©

Current Catcher Pontoon Barges©

Ocean Fortress© Desalination Plant

Original Wave Catcher Barges©

Open Ocean Current Catchers©

Open Ocean Current Catcher© Power Farms

Tidal Area Current Catchers©

River Current Catchers©

Bridge Current Catchers©

Current Catcher Pontoon Barge©

Open Ocean Current Catcher©

With Taunt Moorings

Open Ocean Current Catcher© With

Vertical Tension Leg And Horizontal Moorings

Click for the Open Ocean Current Catcher Frame© Installation Brochure, the Current Catcher© Presentation,

and the Current Catcher Pontoon Barge© Presentation

Click for Video - Marine Energy Corporation Interview at the 2013 All Energy Conference in Aberdeen, Scotland

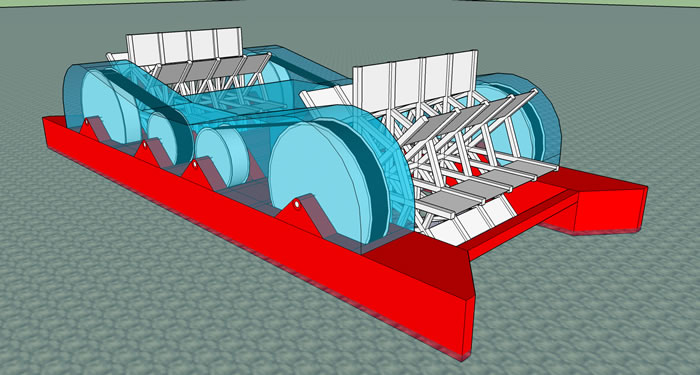

Open Ocean Current Catchers Pontoon Barge©:

High velocity marine currents are found in tidal areas and between land masses like Cuba and Florida and between Cuba and the Yucatan Peninsula. Up to 3 knot currents have been recorded in the Florida Straits. The highest current velocities are usually recorded near the water's surface. There are many concepts that have been patented and some developed to turn marine currents into power, but most of these concepts have underwater mechanical components that are very difficult and expensive to maintain. The "Current Catcher Pontoon Barge" only has structural components below water and no mechanical components underwater. The paddles are underwater structural components that are not subject to wear and are designed to be very large and have very high drag coefficients so they can catch as much force as possible from the high velocity surface currents. The paddle wheels have easily replaceable bearings located above water. Keeping all mechanical equipment above water under a water tight dry enclosure allowing quick and safe maintenance and replacement of wear components and equipment preservation which is a major advantage of the "Current Catcher Pontoon Barges" resulting in maximum uptime and low OPEX.

Other significant advantages of "Current Catcher Pontoon Barges" are that: 1) their pontoons are the lowest cost form of floating offshore structure; 2) they can be built almost anywhere in the world; 3) they can be towed to site and attached to their pre-installed mooring lines and export power cable in less than a day; 4) they are ready to start producing power immediately; 5) their 20m OD paddle wheels supply enough torque to power four 6 megawatt direct drive wind turbine type generators (located under the barge enclosure) at their maximum capacity.

"Current Catcher Pontoon Barges" can also support subsurface current generators (like Marine Energy Corporation's Current Catcher Frames) for additional power generation capacity and provide surface maintenance facilities for the subsurface generators without the need to mobilize special underwater maintenance vessels.

Click for the Current Catcher Pontoon Barge© Presentation.

The US, Mexico and Cuba could jointly work together to develop the best technology for these shared high velocity current areas. "Current Catcher Pontoon Barges" should produce very low LCOE costs in high velocity marine current areas and possibly lower than new onshore wind power plants and new gas power plants.

Design Principles of the Current Catcher Barge:

- Provide the Lowest Cost per Megawatt of any other Marine Current Power Generating Device.

- Convert significant amounts of marine current into power making the power farm projects worth the effort and time of the developers, designers, fabricators, installers and operators.

- Use the lowest cost existing components like four existing 6 megawatt direct drive wind turbine type generators, steel box cross section pontoons.

- Use the lowest cost floating support structure, a pontoon barge.

- Shape the barge's pontoons so they increase the current velocity across the paddles.

- Locate all mechanical and electrical equipment above water in a dry enclosure for safe and fast maintenance and for long term preservation.

- Fly or boat maintenance crews in order to quickly access all mechanical and electrical equipment for maximum uptime.

- Make the pontoon barges able to survive 100 year storms.

- Make the pontoon barges so they minimize mooring systems and associated costs.

- Uses only simple, proven, reliable and low components.

- Uses large low cost, large area and high drag coefficient paddles.

- Install the barge quickly, easily and for the lowest installation costs.

- Make the barge quickly and easily removed for dry docking every 15 years at the lowest possible removal costs. Dry docking is required for repainting every 15 years because that is the maximum life expectancy so far for marine paint.

- The hull can undergo underwater on site inspection every 5 years without barge removal.

- Power generation can start immediately after installation.

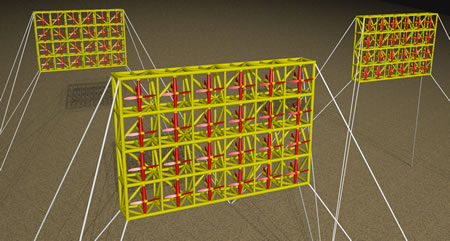

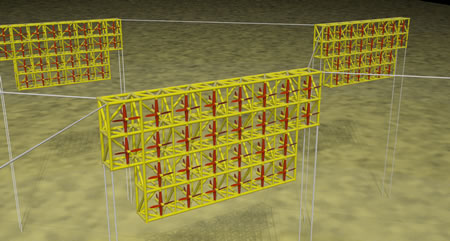

Open Ocean Current Catchers©:

One Open Ocean Current Catcher Frames© can support approximately 24 or more marine current generators with 16 meter OD blades with a total power output of approximately 15 Megawatts in 2.5m/sec flow velocity conditions. Current Catchers© Frames can support fixed generators or current generators that rotate 360 degrees about their vertical axis. The frames can support most types and sizes of generators. The generators chosen will likely be the ones that produce the most power at the lowest cost for the projected surface area of current catcher frame. Generators can be equipped with shrouds to further increase power output / projected area of the frames.

Current Catcher© frames are positively buoyant tubular frames, like those used for offshore platforms for over 50 years. Frame corrosion is prevented below water through the use of anodes and/or impressed current and in the splash zone and above the splash zone with the use of special fiberglass reinforced rubber coatings. Normally, no part of the Open Ocean Current Catcher Frames© extends above the water's surface. The submerged frames are usually deep enough to avoid normal wave loading and ships. These frames can also support surface wave generators (Wave Catchers©), which in the right locations, can add significant power output to each frame. Wave Catchers© and top buoys can provide additional top tension for the Current Catcher© frames and reduce the frame member sizes to further meet the frame’s buoyancy requirements.

Strong currents are often found between two land masses, such as between the Yucatan Peninsula & Cuba, or between Cuba & Florida, and sometimes these locations are also near large population centers minimizing the power transmission losses to these large population centers. Remote areas of high currents can also be used to supply power to all sorts of industrial operations that need significant power but need very few people to run the operation such as: desalination plants, offshore platforms, FPSOs, floating or land based LNG plants, power for the grid, etc.

In summary, Current Catchers©:

- have the ability to survive 100 year storm conditions for minimum investment risk

- allow individual generators to be replaced without removing the frames with a plug and play generator removal system

- can be replaced in a few days if and when major refurbishment may be required, after 25 years for example

- cause no visual or environmental pollution since they are located below the water's surface

- cause no navigational hazards since they are below the draft of all vessels and will be located in clearly marked areas on all navigational charts

- like offshore platforms, will attract and support animal life

- studies have shown that animals will avoid the generators like these due to their sound, and small fish just swim through the slow moving blades

- can be installed and maintained using conventional offshore platform techniques which have been successfully used for decades

- benefit from the fact that the major components already exist like: tested generators, the offshore platform type pipe tubular frames, the mooring systems, etc.

- components that do not exist in these sizes, like uni-direction pulleys with recoil springs and flywheels, can be scaled up from existing proven smaller components

- can be built in fabrication yards located all over the world

- can be transported anywhere in the world by many existing heavy lift vessels

- can be installed quickly and safely with their generators in high current locations

- can be made operational very quickly soon after installation making power output available immediately

- have the best chance of satisfying development economics since they supply the lowest durable support costs, economies of scale, the ability to support almost all types of generators allowing the best one to be selected for the best overall economics